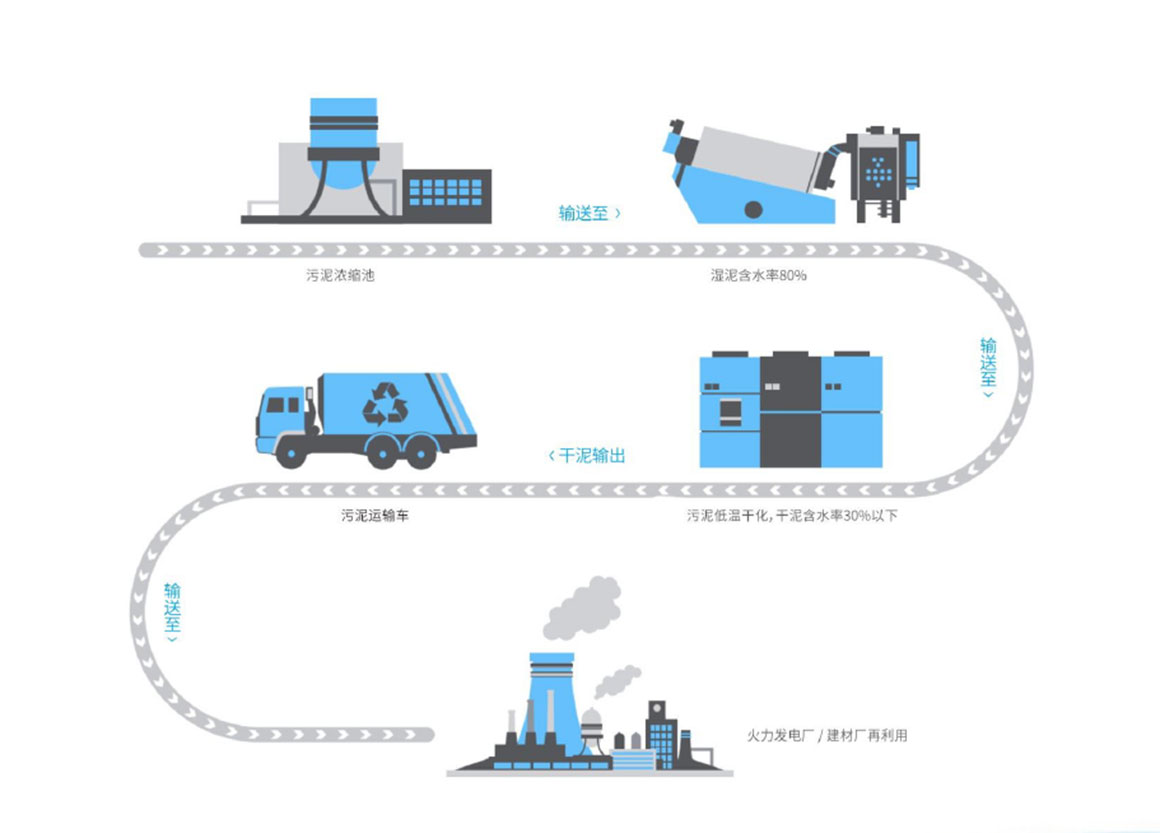

Principle of low temperature sludge drying

Jingchuang environmentally-friendly independently developed sludge low-temperature drying equipment is based on the principle of low-temperature evaporation, condensation, and dehumidification of heat pumps. It uses hot air convection drying to perform low-temperature evaporation and dehydration of wet sludge on the mesh belt, and circulates condensed humid air to make The sludge is dried.

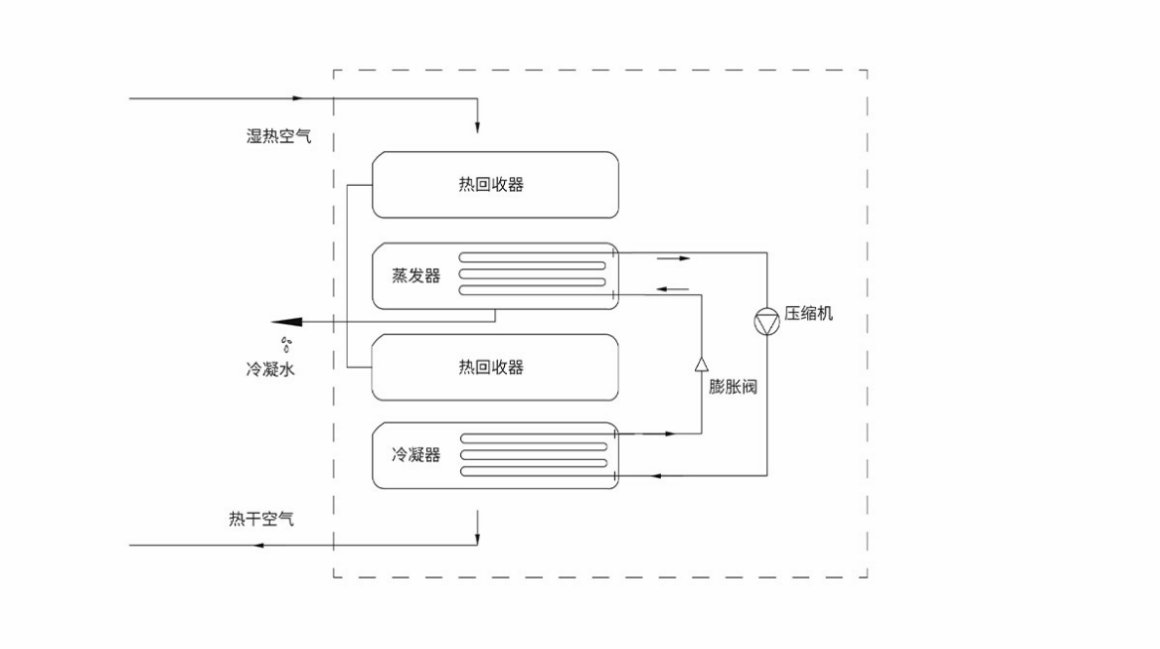

Heat pump principle

Use energy technology heat pump system to cool and dehumidify the humid air from the drying room, and recover the latent heat of moisture condensation to heat the dry air again. It is a combination of dehumidification (dehumidification drying) and heat pump (energy recovery), which is the energy in the drying process Recycling.